OUR STORY

2010: BELLS & WHISTLES

Just like any other parent, engineer and Black Mountain founder Andy Lloyd was keen to get his young children outside and on bikes as soon as he possibly could. He wanted to instil in them his own passion for cycling. So back in 2010, and with nothing but positive thoughts in his head, he visited his local ‘large high street cycle megastore’ and paid £80 for something that resembled a bike for his then five-year-old son. It was red, it had all the bells and whistles (literally) but when he got it home he realised that he had made a mistake… a big mistake!

Firstly, it was an incredibly heavy lump (about 80% of his son’s weight!), the brakes didn’t work properly, the gearing was too hard, and the bars were up somewhere around his son’s chin… it was wrong, just wrong and basically no fun. It was not a pleasurable experience for his son to ride on, or for Andy as a parent watching the struggle! So, he modified the bike, stripped off the heavy accessories, upgraded the braking system and changed the gearing, but it was still heavy and poorly designed, and to add insult to injury, his son soon grew too big for it. Another bike destined for the back of the shed (a scene that has been repeated all over the country on countless occasions).

Firstly, it was an incredibly heavy lump (about 80% of his son’s weight!), the brakes didn’t work properly, the gearing was too hard, and the bars were up somewhere around his son’s chin… it was wrong, just wrong and basically no fun. It was not a pleasurable experience for his son to ride on, or for Andy as a parent watching the struggle! So, he modified the bike, stripped off the heavy accessories, upgraded the braking system and changed the gearing, but it was still heavy and poorly designed, and to add insult to injury, his son soon grew too big for it. Another bike destined for the back of the shed (a scene that has been repeated all over the country on countless occasions).

2011: BIKE SHAPED OBJECTS

Andy recognised the inadequacy of the bike he had bought and of the many other existing children's bikes that were on the market. They just weren't designed for a young rider’s needs – they were just shrunken adult bikes. There were many things that he wasn’t happy with, but crucially the bikes failed to recognise that the young rider was always growing and changing in size, weight, strength, ability and speed. Also that many children changed from not being able to ride, to being able to ride, within a matter of months, weeks, days or even hours.

After some further research Andy found that most kids bikes took a ‘disposable toy’ approach – incredibly heavy (and over-engineered) steel frames, clunky and poorly made and designed – a toy for the driveway, but not a rideable bike (Andy would later find out that within the bike industry, these kids bikes were referred to as BSO’s – bike-shaped-objects!).

Some higher-end kids’ bikes did exist, but these still failed to address the changing size, power and ability of the growing rider, as they still were based on traditional ‘one–size’ fixed frames. This meant parents had to either buy a bike which was too big (and hope their child grew into it – really not a good idea when they are learning) or buy a bike that fits now, that will be too quickly outgrown.

After some further research Andy found that most kids bikes took a ‘disposable toy’ approach – incredibly heavy (and over-engineered) steel frames, clunky and poorly made and designed – a toy for the driveway, but not a rideable bike (Andy would later find out that within the bike industry, these kids bikes were referred to as BSO’s – bike-shaped-objects!).

Some higher-end kids’ bikes did exist, but these still failed to address the changing size, power and ability of the growing rider, as they still were based on traditional ‘one–size’ fixed frames. This meant parents had to either buy a bike which was too big (and hope their child grew into it – really not a good idea when they are learning) or buy a bike that fits now, that will be too quickly outgrown.

2012: EUREKA - INSPIRATION AT 30,000FT

Andy is a manufacturer and engineer whose background lies in developing products for the world’s leading automotive and motorsport companies – so he decided he could to do a better job. He set about designing the ultimate kid’s bike, with the specific goal of making a lightweight bike that one that would last more than just one ‘growing year’. As his children grew he recognised that young riders go through really significant changes during their early years, and he wanted to make a bike that would properly address that problem.

His real ‘eureka moment’ came one day in 2012 when he was travelling for work (at about 30,000ft over Munich!). He knew that he needed to make a light bike, with properly scaled components… but he would also have to tackle the ultimate issue of making a bike that grew as your child did. Could it then transform into a pedal bike and change size and gearing as the child grows in size, strength and ability?

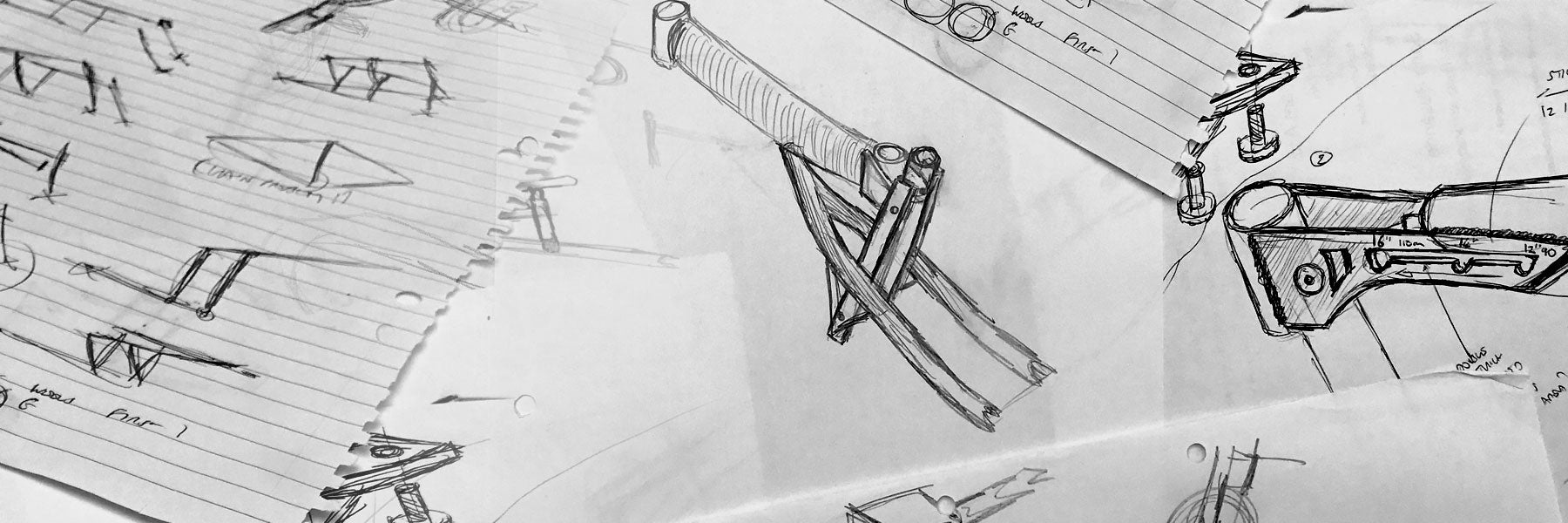

Doodling away, trying to design a frame would allow for this, the idea of the ‘growing triangle’ frame was born. He scribbled his rough idea down on the back of the in-flight magazine (a cliché, but it is true) and the idea of Black Mountain and the EPOK growing frame design was born.

His real ‘eureka moment’ came one day in 2012 when he was travelling for work (at about 30,000ft over Munich!). He knew that he needed to make a light bike, with properly scaled components… but he would also have to tackle the ultimate issue of making a bike that grew as your child did. Could it then transform into a pedal bike and change size and gearing as the child grows in size, strength and ability?

Doodling away, trying to design a frame would allow for this, the idea of the ‘growing triangle’ frame was born. He scribbled his rough idea down on the back of the in-flight magazine (a cliché, but it is true) and the idea of Black Mountain and the EPOK growing frame design was born.

2013: THE GARDEN SHED, FOAM BOARD & LEGO…

Returning home, he set himself up in his garden shed/workshop at the foot of Skirrid Mountain in Monmouthshire’s Black Mountains and during any free time (away from the ‘day job’ and the demands of Formula 1, and MotoGP customers) he started work on developing his ideas.

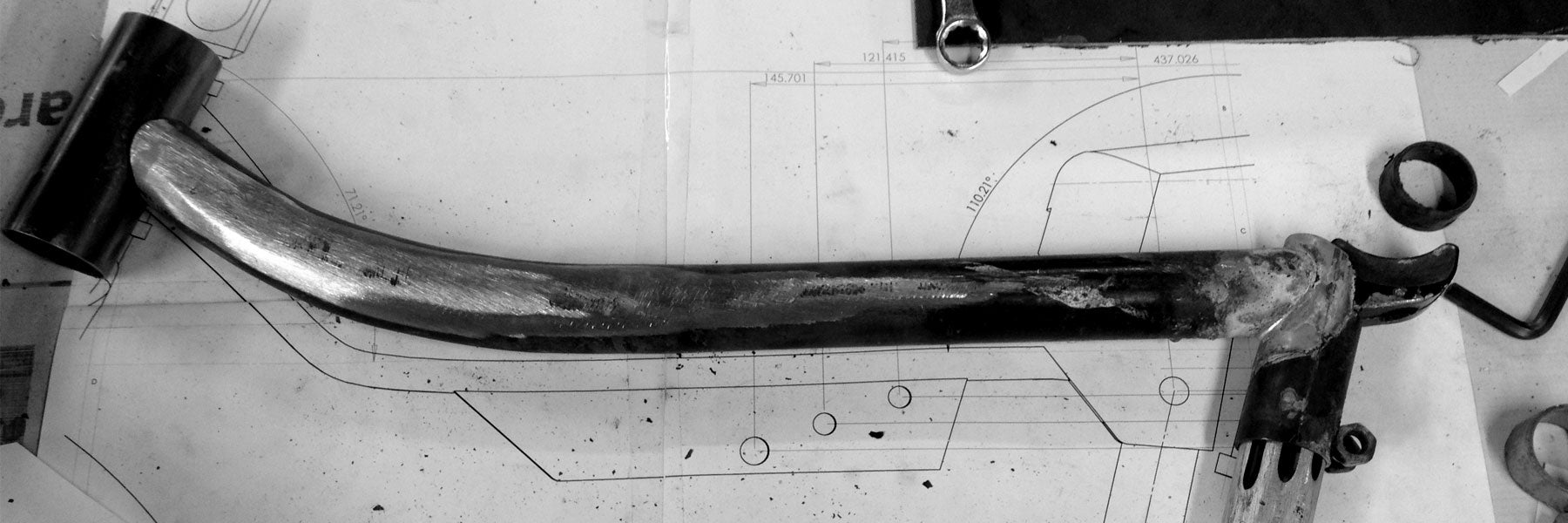

Like all good engineers, Andy’s sketches turned first to Lego models, the Lego models turned to foamboard models, and soon Andy was welding up his first prototype ‘mule’, borrowing wheels, bars and other bits from a job lot of kids bikes he salvaged off eBay.

His first prototype was not a thing of beauty, but it made into reality the idea of a bike that could grow as your child does. It was rough and crude, but it had captured the essence of what would become known as Black Mountain’s EPOK™ range of children’s bikes – he’d cracked how to make a lightweight bike that could and change gearing as the child gets bigger, more confident and stronger.

Andy developed his mule over many months, with frantic and patient testing by his own rapidly growing children (many a test ride was conducted in pyjamas before story time!). After a few tweaks, Andy realised that he was onto something. His gem of an idea would work. Two more mules (and plenty of testing) later and he was getting close to making his dreams into reality.

Like all good engineers, Andy’s sketches turned first to Lego models, the Lego models turned to foamboard models, and soon Andy was welding up his first prototype ‘mule’, borrowing wheels, bars and other bits from a job lot of kids bikes he salvaged off eBay.

His first prototype was not a thing of beauty, but it made into reality the idea of a bike that could grow as your child does. It was rough and crude, but it had captured the essence of what would become known as Black Mountain’s EPOK™ range of children’s bikes – he’d cracked how to make a lightweight bike that could and change gearing as the child gets bigger, more confident and stronger.

Andy developed his mule over many months, with frantic and patient testing by his own rapidly growing children (many a test ride was conducted in pyjamas before story time!). After a few tweaks, Andy realised that he was onto something. His gem of an idea would work. Two more mules (and plenty of testing) later and he was getting close to making his dreams into reality.

2014: TIME TO GET SERIOUS

Things then stepped–up a gear in 2014 when he employed the young, enthusiastic and talented product and industrial designer Greg Hampton (he’s cycling mad too). Greg became Lead Designer and took on all of Andy’s ideas, drawings and prototypes and set to the task of making them into something tangible, a real working bike that could be manufactured and then sold to the public.

Using the latest 3D CAD systems (just as used in Andy’s automotive engineering business), Greg began to design, test, simulate and develop the first EPOK designs. Greg knew that the bikes needed to combine a light frame that could grow with the child (in size, geometry and speed), matched with top-end, scaled down componentry and wheels (including really good safe brakes designed for small hands) resulting in a super light-weight, and super cool bike.

By the end of 2015 (and with significant legal help from Andy’s brother Matt) the first of Black Mountain’s patents were filed - this would go onto be successfully granted in the UK, and deployed globally – the first bicycle frame to grow its triangular core.

Using the latest 3D CAD systems (just as used in Andy’s automotive engineering business), Greg began to design, test, simulate and develop the first EPOK designs. Greg knew that the bikes needed to combine a light frame that could grow with the child (in size, geometry and speed), matched with top-end, scaled down componentry and wheels (including really good safe brakes designed for small hands) resulting in a super light-weight, and super cool bike.

By the end of 2015 (and with significant legal help from Andy’s brother Matt) the first of Black Mountain’s patents were filed - this would go onto be successfully granted in the UK, and deployed globally – the first bicycle frame to grow its triangular core.

2016: THE DEVIL IS IN THE DETAIL

The project was now firing on all cylinders. The first of many 3D printed (additive manufacturing) prototypes were made to ensure that every element of the bike would work as it should. Visits to factories and suppliers, hundreds of emails, Skype calls and meetings in Europe and Taiwan followed.

There are over 100 separate parts in each of the EPOK bikes, every one of which has been specifically sourced, modified, or designed by Andy and Greg. After a period of further development – perfecting, honing and tweaking the design – the first aluminium prototypes were ordered.

There are over 100 separate parts in each of the EPOK bikes, every one of which has been specifically sourced, modified, or designed by Andy and Greg. After a period of further development – perfecting, honing and tweaking the design – the first aluminium prototypes were ordered.

2017: RELOCATION & PRODUCTION STARTS

Things finally came to fruition in 2017. In February the company moved into new premises just outside the village of Raglan (set in what used to be the hunting grounds of the famous Raglan Castle). A month later the first pre-production bikes arrived and final testing could begin. This include lab testing bikes to destruction, subjecting them to thousands of cycles of testing, real world testing with friend’s kids, and the ultimate test – giving it to Greg to jump, hop and thrash!

After some further ‘tweaks’ the first batch of complete bikes (the PINTO and SKOG are the first two models in the EPOK series) were ordered. At the end of November the warehouse started filling up as the first shipment arrived.

After some further ‘tweaks’ the first batch of complete bikes (the PINTO and SKOG are the first two models in the EPOK series) were ordered. At the end of November the warehouse started filling up as the first shipment arrived.

2018: THE WORLD’S MOST ADVANCED KIDS BIKE

It has been a long process, but no corners have been cut. We believe that the Black Mountain’s EPOK series are more advanced than any other child’s bike currently on the market. The PINTO and SKOG are incredibly lightweight, both are ‘two–size’, ‘two–speed’ and can be dialled–in and tuned–up to suit the rider.

All of the technology and fine details that Andy and Greg have slaved over – UP:SCALE, IN:GEAR, GO:LOW, MY:SIZE the belt drive, the honed geometry, the proportionately sized components – all of these elements have come together to produce the ultimate kid’s bike.

The dream has become a reality.

All of the technology and fine details that Andy and Greg have slaved over – UP:SCALE, IN:GEAR, GO:LOW, MY:SIZE the belt drive, the honed geometry, the proportionately sized components – all of these elements have come together to produce the ultimate kid’s bike.

The dream has become a reality.